Every parent wants their baby to be comfortable, safe, and dressed in clothes that feel just right. But behind every cozy romper or soft bodysuit lies a technical factor that’s often overlooked: fabric weight, also known as GSM (grams per square meter).

Fabric weight plays a critical role in how baby clothes feel, perform, and protect. From breathability to warmth to washing durability, choosing the wrong GSM can ruin even the best-designed piece.

At Fumao Clothing, we manufacture custom babywear for premium global brands. We’ve helped our clients match the perfect fabric weight to their seasonal and regional needs. In this article, I’ll break down why GSM matters, how to choose the right range, and what common mistakes to avoid when developing infant apparel.

What Does Fabric Weight (GSM) Mean in Baby Clothing?

GSM stands for “grams per square meter.” It measures how much a square meter of fabric weighs. The higher the GSM, the heavier and usually thicker the fabric is.

How Does Fabric GSM Impact Baby Garment Performance?

Each GSM range affects wearability, safety, and practicality. Here’s a breakdown:

| GSM Range | Characteristics | Suitable For |

|---|---|---|

| 100–130 | Lightweight, airy, soft | Summer onesies, underlayers, newborn items |

| 140–180 | Medium-weight, durable yet breathable | Year-round bodysuits, pajamas, knit tees |

| 190–240 | Heavier, warm, structured | Hooded rompers, sweatshirts, winter styles |

For example, we use 120gsm organic cotton jersey for our summer rompers—it’s light enough for air flow but sturdy enough to prevent see-through. For winter hoodies, we go with 220gsm brushed fleece to keep the baby warm.

What Are Common GSM Materials Used in Babywear?

Here are a few babywear-friendly materials and their typical GSMs:

- Cotton Rib Knit – 180–200gsm

- Bamboo Jersey – 160–180gsm

- Interlock Cotton – 200–220gsm

- Brushed Fleece – 220–260gsm

- Waffle Knit – 170–200gsm

We recommend using tools like the GSM Cutter or GSM test by SGS to verify your fabric supplier’s claims—especially if fabric shrinkage is a concern.

Why Is Low GSM Risky for Babywear Durability and Safety?

Lightweight sounds appealing for comfort—but if the GSM drops too low, issues arise quickly, especially in real-world usage.

Can Thin Fabrics Be See-Through or Tear Easily?

Yes. Fabrics under 120gsm often fail opacity tests, especially in lighter colors like white, peach, or cream. We’ve seen brands forced to relabel their products or switch packaging because of transparency complaints.

Also, low GSM fabrics are prone to:

- Snagging during machine wash

- Curling at seams due to poor fabric stability

- Neckline overstretching in pull-over styles

To meet durability expectations, we usually suggest using GSM above 150 for items worn daily or frequently washed.

Do Lower GSM Fabrics Compromise Stitching or Printing?

Absolutely. Stitching density must align with fabric density. If GSM is too low, seams may create puckering or holes. Similarly, screen printing or heat transfer logos may cause the fabric to distort or ripple under heat pressure.

We work with trusted labs like Intertek to conduct burst strength tests and assess seam durability—especially important for brands exporting to regulated markets like the U.S. and EU.

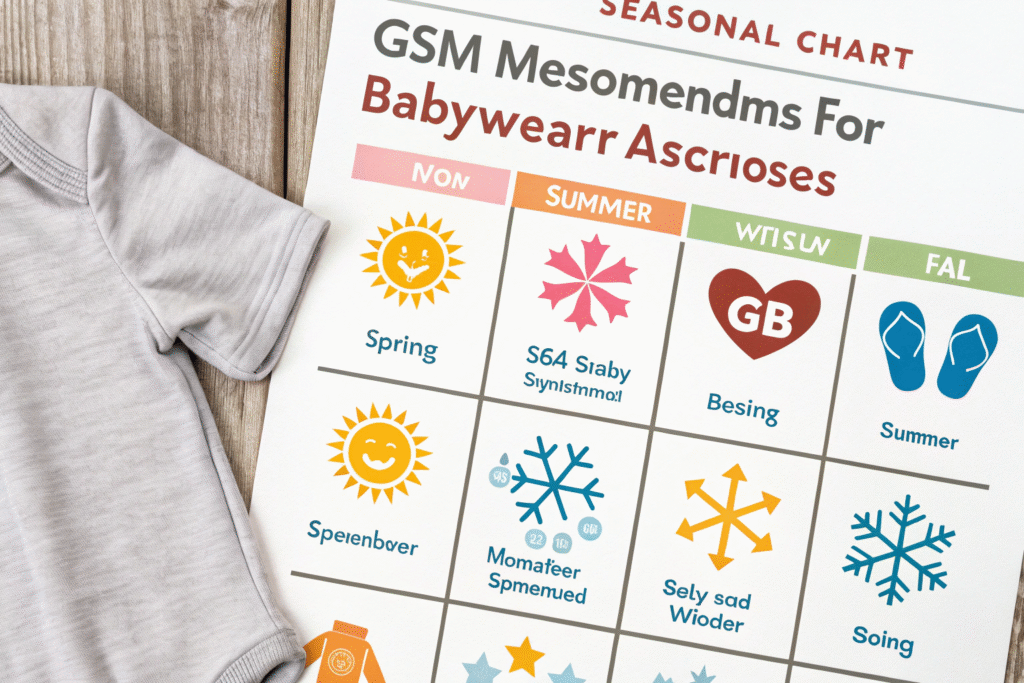

How to Choose the Right GSM by Season and Use Case?

One of the most frequent questions we get from clients is: “Which GSM should I use for my collection?” The answer depends on season, target climate, and product category.

What’s the Best GSM for Summer Baby Clothes?

For hot weather, breathability is key. Here’s what we use:

- 115–130gsm bamboo jersey for short sleeve bodysuits

- 130–150gsm cotton pointelle for newborn vests and underlayers

- Single jersey (120gsm) for breathable, everyday wear

Don’t go below 110gsm unless it’s for undershirts only, and always test shrinkage rates—low GSM cotton tends to shrink more if not pre-washed or pre-shrunk.

What GSM Works Best for Winter Infantwear?

Winter babywear should offer insulation without bulk:

- 220–260gsm brushed fleece for rompers or hoodie sets

- 180–200gsm interlock cotton for long pajamas

- 190–230gsm cotton/spandex blends for structured leggings

Parents buying winter clothing for babies want a soft touch with body heat retention. We often laminate the inner fleece layer or use a carbon brushing technique to enhance the softness and warmth.

What GSM Mistakes Should Brands Avoid in Baby Garment Sourcing?

Choosing the wrong GSM can cost a brand more than just returns—it hurts reputation. Here are the most common sourcing errors.

Is It Risky to Mix GSM Across Sizes or SKUs?

Yes. Inconsistent GSM across the same SKU (e.g., size 3M and 18M) can lead to customer confusion. Babies grow fast, and repeat customers will notice if a larger size feels thinner or looser than smaller ones.

We always maintain a uniform GSM policy across all sizes of a single design and adjust pattern grading to ensure fit consistency.

Should You Trust Suppliers Without GSM Test Reports?

No. Many small mills quote GSM based on estimated greige fabric weight, not the finished fabric. Always request:

- Lab-tested GSM data

- Shrinkage reports

- After-wash GSM variation (it often drops 5–10%)

Our mill partners provide certified test reports by labs like Bureau Veritas or SGS upon request for each production run.

How Does Fumao Help Brands Manage GSM Correctly?

As a custom babywear manufacturer, we take GSM management seriously. From sampling to production, it’s tracked at every step.

Do You Offer GSM Swatch Books and Test Data?

Yes. We offer:

- GSM-labeled swatch book with various knit types

- Digital GSM map for each approved fabric

- Optional third-party fabric verification

Before production, we send clients a GSM declaration form. We also compare actual production fabric weight with lab-tested samples to ensure consistency.

How Do You Align GSM With Printing, Dyeing, and Embroidery?

GSM isn’t just about thickness—it also affects downstream processing. We adjust:

- Stitch type based on GSM (e.g., flatlock vs overlock)

- Dyeing temperature and time (lighter GSM fabrics absorb dye faster)

- Heat press duration to avoid burning thin knits

This level of detail ensures that whether we’re making a 120gsm bamboo romper or a 240gsm fleece hoodie, the output feels balanced, wearable, and baby-friendly.

Conclusion

Fabric weight isn’t just a technical spec—it’s a direct contributor to baby comfort, safety, and product quality. Getting GSM right means fewer returns, happier parents, and stronger brand loyalty.

At Shanghai Fumao Clothing, we guide our clients through every step of GSM selection and validation. Whether you’re launching your first babywear line or refining a seasonal collection, we’re here to help you make informed, durable choices.

To request a GSM swatch kit or learn how our factory ensures fabric quality from fiber to finish, reach out to our Business Director Elaine at strong>elaine@fumaoclothing.com. Let’s create babywear that parents trust—and little ones love.