Every garment starts with an idea—but how does that idea turn into something real? As a children’s clothing manufacturer, I’ve worked with countless brands to bring their concepts to life. Some arrive with just a sketch. Others have a mood board or a theme. But all want the same thing: stylish, functional garments that meet market needs. The process of designing clothes is structured, creative, and highly collaborative.

The clothing design process includes research, sketching, material selection, prototyping, sample revision, and production planning. Whether it’s fashion or functional apparel, every step must align with brand vision and market demand.

If you’re a buyer, brand owner, or product developer, understanding this process will help you communicate better with your manufacturer and avoid costly revisions. Let me walk you through how we do it at Fumao Clothing.

What are the first steps in designing a clothing line?

The beginning of any successful design journey is rooted in strong research and a clear target audience.

Designing a clothing line starts with trend forecasting, customer profiling, and theme development. This is followed by initial sketching, both by hand and digitally.

How do designers research current trends?

Fashion designers rely on trend platforms like WGSN and Trendstop to analyze color palettes, silhouettes, and seasonal themes. For children’s wear, playful functionality and fabric safety are top priorities.

In our case, we regularly browse Pantone color predictions and European trade show reports like Playtime Paris to gather insights.

How do you define your target audience?

Designing toddler clothes for American parents is different from creating teen streetwear for European boys. We often help brands refine their audience profiles: age, budget, lifestyle, and even where they shop. Sites like Statista provide demographic data that supports our targeting choices.

At Fumao, we always ask our clients about their “hero customer” before starting sketches.

What tools and techniques are used to create clothing designs?

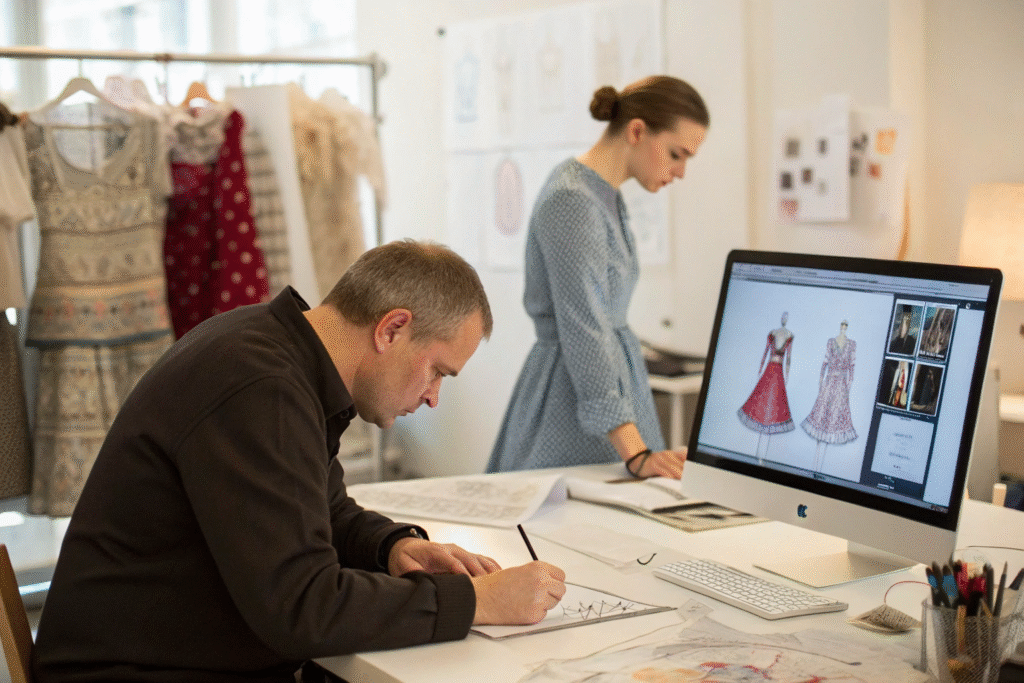

Once the idea is clear, it’s time to sketch, render, and digitize.

Clothing designs move from rough hand sketches to detailed CAD drawings, tech packs, and fabric mapping. Design software like Adobe Illustrator and CLO3D are widely used.

What is a tech pack and why is it essential?

A tech pack is a blueprint for garment manufacturing. It includes measurements, fabric codes, colorways, trims, stitching instructions, and label placement. Without it, factories cannot guarantee consistency or quote accurately.

At Fumao, we offer free tech pack refinement to help clients avoid confusion down the line. It’s especially crucial for multi-style children’s collections where proportions vary by age.

Which software is most commonly used for fashion design?

Adobe Illustrator remains the standard for 2D sketching. For 3D visualization, CLO3D is gaining popularity. It helps simulate fabric drape, fit, and movement. These tools speed up decision-making and reduce the number of physical samples needed.

Many of our European clients provide CLO files, and we convert them into production-ready formats in-house.

How are prototypes and samples developed?

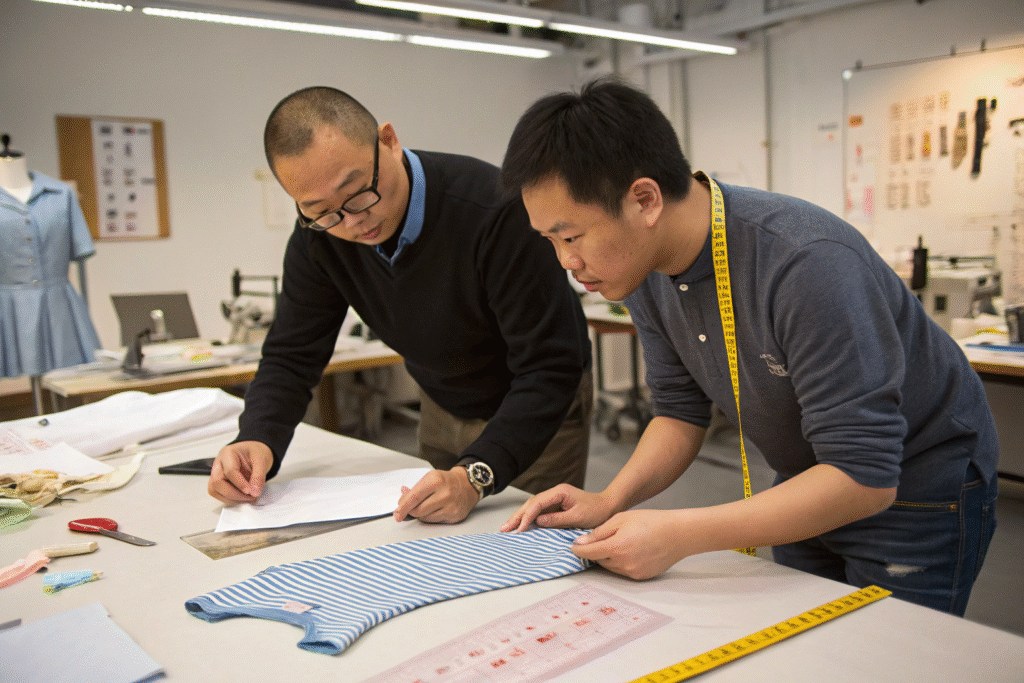

This stage transforms imagination into physical reality. It’s where issues surface—and get fixed.

After design approval, sample garments are developed using real materials. Fit tests, fabric shrinkage checks, and construction reviews follow before final approval.

How are fabric selections finalized?

Before a sample is made, fabric swatches must be approved. For children’s wear, safety, softness, and stretch are key. We offer certified GOTS organic cotton and OEKO-TEX dyed knits.

We also conduct GSM tests and wash trials. If a fabric pills or fades during testing, we switch suppliers. A bad fabric ruins even the best design.

What happens during a fit session?

Once the sample is sewn, it’s worn by a model (or mannequin) matching the target size. Fit sessions check for mobility, neckline depth, armhole position, and body proportions. According to Techpacker, brands usually revise samples two to three times before confirming production.

We provide clients with photo fit reports and measurement charts after each round.

What happens after a clothing design is approved?

The final stage includes cost confirmation, bulk planning, and production scheduling.

Once the design is approved, garment factories handle costing, production planning, and DDP logistics setup. Timing is critical, especially for seasonal launches.

How is production costing calculated?

We break down costs into fabric, trims, labor, packaging, inspection, and shipping. Each component is listed transparently. Sites like Sourcemap help visualize supply chain breakdowns.

Clients are encouraged to finalize order volumes early—larger orders lower unit costs due to fabric yield and machine setup optimization.

What is the lead time between design approval and delivery?

Lead times range from 30 to 60 days, depending on style complexity and factory load. At Fumao, our 5-line facility processes about 10,000 units per day. We prioritize repeat clients and pre-booked slots.

To prevent delays, we maintain backup fabric stock and offer DDP delivery via our freight partners.

Conclusion

Designing clothes isn’t just about creativity. It’s about planning, communication, and consistency. From trend research to final bulk delivery, every stage needs coordination between brands and factories. At Fumao Clothing, we help clients navigate this journey with clarity and care. Whether you’re a startup building your first capsule collection or a retail giant planning next season, understanding the clothing design process helps you make better, faster, and smarter decisions.