Sampling is the foundation of every successful capsule. Done right, it saves time, avoids waste, and makes your product shine. Done wrong, it leads to delays, mistakes, and missed launch windows.

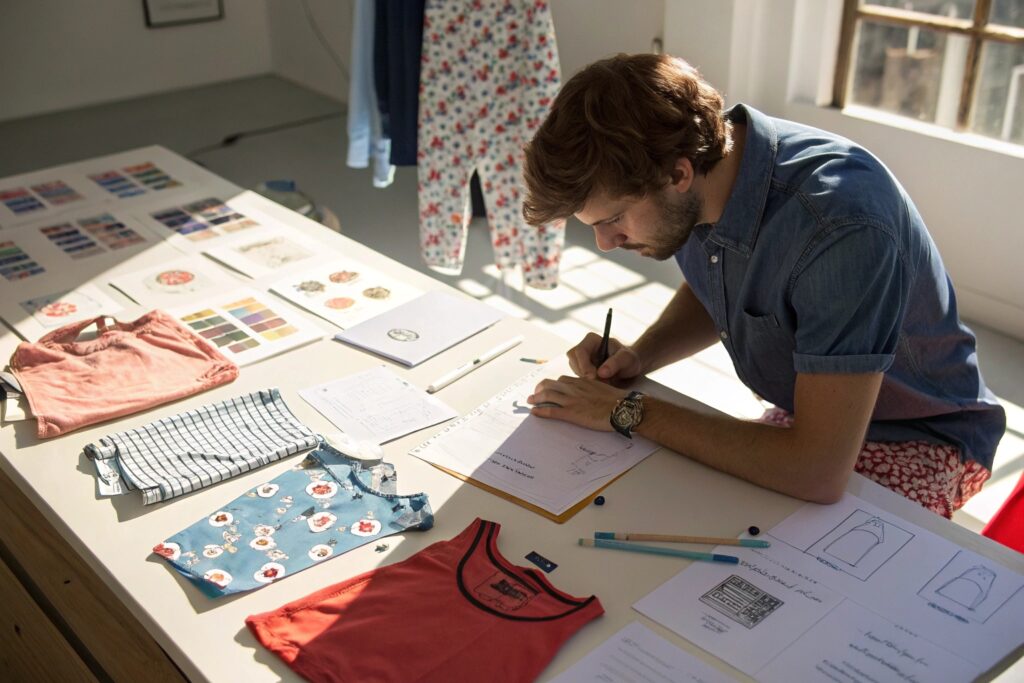

Our kidswear sampling process is designed for capsule collections—fast, flexible, collaborative, and optimized for low-MOQ fashion testing and fast decision-making.

If you’re building your next capsule drop, this guide will show you exactly how we handle sampling to support agile, high-quality, small-batch production.

Which 7 steps are involved in the sampling process?

Sampling isn’t just about making a prototype—it’s a complete cycle from idea to approval.

The 7 key steps in our kidswear capsule sampling process are: concept review, spec development, material sourcing, sample creation, revision handling, fit approval, and pre-production confirmation.

How does our 7-step sampling process reduce production errors and accelerate capsule timelines?

Here’s how our sampling cycle works at Fumao Clothing:

- Concept Review – We discuss your mood board, inspiration, target market, and capsule goals.

- Spec Development – Our pattern makers translate your sketches or references into real garment specs.

- Material Sourcing – We source or suggest in-stock MOQ-friendly fabrics that fit your design vision.

- Sample Creation – First samples are produced, labeled, and documented.

- Revision Handling – You give feedback; we revise fast—often in under 7 days.

- Fit Approval – We confirm fit through detailed size sets or live models depending on complexity.

- Pre-Production Confirmation – Final pre-production sample is approved for bulk order.

Each stage is transparent. You receive photos, updates, and measurements. We work fast because capsules move fast.

Our system reduces guesswork and helps capsule brands launch on time with confidence.

Why is sampling especially important for small capsule collections?

Capsules often feature only 3–5 key styles. That means each one carries more weight. A poor fit or wrong fabric on just one SKU can compromise the whole collection.

Because capsule quantities are limited, there’s no room for “learning in bulk.” Sampling is your safety net. That’s why we allow even two or three rounds of changes within a single MOQ-friendly project.

We build it right before you produce it—so there are no surprises later.

How is sampling done in pharmaceutical industry?

While our focus is fashion, it’s helpful to understand how other industries approach sampling for quality and compliance.

In pharma, sampling is a regulatory process where representative batches are selected and tested to verify product integrity, consistency, and compliance.

How do pharma and fashion sampling processes compare?

While pharmaceutical sampling focuses on chemistry and compliance, fashion sampling focuses on aesthetics and wearability. But both share one core idea: test small to ensure big success.

In pharma:

- Samples are pulled from each production lot.

- Lab testing is done for purity, dosage, and packaging.

- Results are recorded in compliance with regulations.

In fashion:

- Samples test fit, stitching, and style execution.

- Revisions are based on wearability and brand positioning.

- Final approval reflects market readiness.

Both industries use sampling to validate quality before full-scale launch. In our case, we help capsule brands catch problems early—just like a lab test prevents product recalls.

What can fashion sampling learn from pharmaceutical sampling?

Documentation. At Fumao Clothing, we track every change in samples with photo logs, timestamped feedback, and status reports. This helps capsule brands make informed decisions, especially across remote teams.

Capsule collections may not be FDA-regulated—but your customer still expects perfection. That’s what smart sampling helps deliver.

What are the 5 steps for the sampling design process?

Sampling design determines how you create samples that truly reflect your target product.

The 5 steps of our sampling design process are: define objectives, choose sample types, determine specifications, prototype development, and finalize for approval.

How do these 5 steps create more accurate and market-ready capsule samples?

Here’s how we break it down at Fumao Clothing:

-

Define Objectives

What are you testing? Fit? Fabric? Print technique? Launch proof of concept? This defines your scope. -

Choose Sample Types

Do you need proto, size sets, or marketing samples? For capsules, we often create 1 proto + 1 fit sample + 1 media sample per style. -

Determine Specifications

We build clear tech packs: measurements, trims, colorways, and print placements. Even for 3-SKU drops, accuracy matters. -

Prototype Development

Samples are cut, sewn, and detailed in-house by our sampling line—not our mass-production line. -

Finalize for Approval

You receive samples, provide feedback, and approve once everything is right. We proceed only with your green light.

This process prevents last-minute panic. It also empowers brands to make better merchandising and marketing decisions.

Why is good sample design essential for lean inventory?

Because the better your sample, the more accurately you can forecast. If your media sample is well-shot, you can use it to gauge preorder interest. If your fit sample is perfect, your returns drop.

Sampling design is your best planning tool. And that’s exactly why capsule brands need it more—not less.

What are the advantages of sampling in quality control?

Sampling doesn’t just help your product look good—it helps it perform well.

Sampling improves quality control by identifying fit issues, construction flaws, and material inconsistencies early—before they affect your production.

How does sampling reduce returns and improve customer satisfaction?

When we sample, we catch problems early. Examples:

- Fabric pills after wash? Swap it.

- Neck opening too small? Adjust spec.

- Print color too faded? Change method.

Each of these issues, if discovered post-launch, means returns and lost trust. But during sampling? They’re just fixes.

We’ve seen capsule brands cut return rates in half after improving their sampling workflow. That translates to happier customers and higher margins.

Why is sampling even more critical in kidswear?

Because kids move more. They pull, stretch, roll, and tumble. Kidswear must be safe, flexible, and durable. That’s why our sampling process includes fit testing, snap security checks, and trim testing.

We verify every detail—from elastic stretch to zipper guard placement. Especially in capsule runs where there’s no second chance to fix post-launch, sampling is your strongest defense.

Conclusion

Capsule success starts with smart sampling. Our 7-step, quality-focused, startup-friendly process ensures your kidswear collection is ready for market—fast, flexible, and flawlessly executed.