The phrase “Made in China” used to carry a connotation of mass production and budget fashion. But in 2025, that narrative has dramatically shifted — especially in the children’s fashion sector.

Yes, Chinese factories not only produce high-end kids fashion — they lead it in volume, quality, and global supply capabilities. Top U.S. and European babywear brands now rely on Chinese manufacturing for precision, compliance, and scalable luxury.

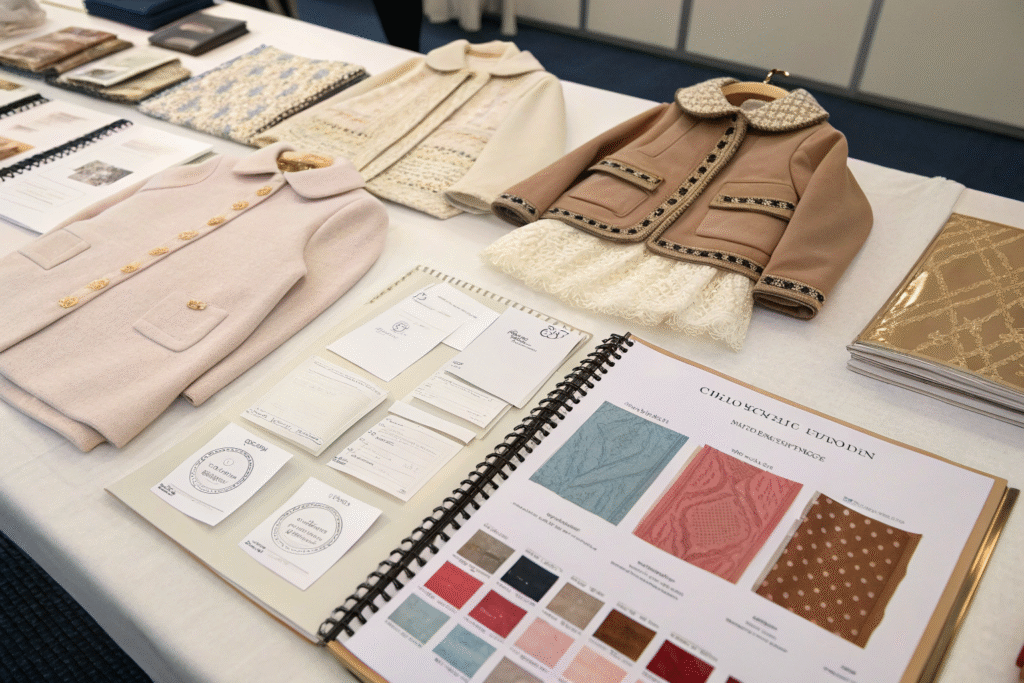

At Fumao Clothing, we proudly serve several mid- to high-tier children’s apparel brands who demand top-tier fabrics, safety standards, and sophisticated craftsmanship. In this article, I’ll show you how — and why — Chinese factories are now fully capable of delivering premium kidswear collections that rival European output.

What Defines “High-End” in Kidswear Manufacturing?

High-end kids fashion goes beyond ruffles and bows. It requires a full ecosystem of detail-focused production — from fabric sourcing and sizing precision to safety testing and brand-worthy packaging.

Luxury babywear isn’t about logos. It’s about materials, comfort, fit, and ethical production.

What Fabrics and Trims Are Used in Premium Kids Fashion?

The foundation of luxury kidswear lies in premium raw materials. These include:

- Organic GOTS-certified cotton

- Egyptian cotton interlock

- Bamboo rayon

- Brushed modal blends

- OEKO-TEX® dyed lace trims

- Nickel-free snap buttons

- Sustainable zippers from brands like YKK

Factories like ours source these materials from certified Chinese mills listed on Textile Exchange or approved OEKO-TEX supplier lists. This ensures not only softness but hypoallergenic safety for baby skin.

What Construction Details Set High-End Kidswear Apart?

Precision cutting, double-stitched seams, clean tagless finishes, and hand-placed embellishments define the category. Factories offering flatlock stitching and multi-needle hemming machines ensure smoother construction. Toddler garments must endure dozens of washes without warping, which requires pre-shrunk fabric and tested shrinkage rates under ISO 6330.

Brands like Bonpoint and Tartine et Chocolat have inspired a generation of boutique buyers — and Chinese factories now replicate this level flawlessly.

How Do Chinese Factories Ensure Premium Quality Control?

Premium kidswear requires more than visual appeal — it needs to pass rigorous quality and safety benchmarks. Chinese factories that serve high-end brands implement both in-house QA systems and external lab testing to meet these standards.

Quality is no longer a bonus — it’s built into the production system from day one.

What Tests Are Common in High-End Kids Garment QC?

- Fabric shrinkage (ISO 5077)

- Seam strength (ASTM D1683)

- Colorfastness to saliva/sweat (EN ISO 105-E04)

- Snap pull force (CPSIA: 15 lb minimum)

- Flammability (16 CFR 1610 for general wear, 1615/1616 for sleepwear)

Most reputable factories partner with SGS, Intertek, or TÜV Rheinland for third-party reports. These results are shared with brand buyers during final inspection or certification review.

How Do Chinese Factories Track Consistency Over Time?

Factories like Fumao follow the AQL 2.5 standard and conduct pre-production, inline, and final inspections for every batch. Digital QC dashboards, fabric lot traceability, and barcoded tracking labels are now standard. Some high-end suppliers use PLM (Product Lifecycle Management) systems to reduce variation between runs — especially important for scaled-up retail.

Can China Deliver Bespoke and Custom Kidswear at Scale?

Customization is at the heart of premium kids fashion. Whether it’s a monogrammed onesie or a capsule holiday collection, top-tier brands demand small-batch agility with luxury-level finishing.

Yes, Chinese factories can now produce custom, premium kidswear — at both boutique and retail scale.

What Customization Services Do High-End Factories Offer?

- CAD-assisted tech pack development

- In-house embroidery and heat transfer printing

- Low MOQ dye-to-match (Pantone-matched dyeing)

- Multi-size grading for 0–8Y across global markets

- Bespoke packaging (organic cotton bags, rigid boxes, etc.)

At Fumao, for example, we’ve helped European brands develop private-label organic babywear lines featuring water-based prints, minimalist brand tags, and recycled packaging — all while meeting BSCI and WRAP compliance.

What MOQ and Lead Times Apply for High-End Orders?

Premium production doesn’t mean high MOQs. Many certified Chinese factories offer 300–500 pcs/style with a 25–35 day production window — even faster for repeat designs. For custom dyeing or embroidery, timelines may extend by 5–7 days, but remain faster than European sourcing.

Use suppliers that support DDP models to control delivery speed and avoid customs delays.

Do Western Luxury Brands Already Source Kidswear from China?

The truth is, many well-known Western kids fashion labels already source — or have quietly sourced — from China for years. The stigma is gone.

What matters now is the quality and compliance of the factory, not its geography.

Which Types of Brands Work with Chinese Manufacturers?

- Mid-premium DTC brands like Monica + Andy

- Private-label babywear sellers on Nordstrom

- Subscription clothing boxes (e.g., Kidpik)

- Eco-forward toddlerwear startups targeting Amazon Climate Pledge Friendly

These buyers don’t advertise their sources — but they all demand certified fabrics, safety-tested construction, and scalable supply. All of which Chinese manufacturers like us deliver daily.

Why Do These Brands Trust Chinese Production?

- Decades of vertical integration (fabric to finishing)

- Rapid prototyping and sample iteration

- Competitive pricing with premium quality

- Robust compliance with CPSIA, GOTS, OEKO-TEX, etc.

At Fumao Clothing, we provide complete transparency — including video factory tours, certification documents, inspection reports, and DDP shipping. This has allowed boutique U.S. and EU brands to grow with confidence, even from overseas.

Conclusion

The question is no longer “Can Chinese factories produce high-end kids fashion?” — but rather, “Which ones are doing it best?”

With advanced machinery, certified fabrics, skilled labor, and a growing understanding of global luxury standards, Chinese factories are now a core player in the premium babywear space. From bespoke embroidery to third-party lab compliance, the supply chain is no longer a barrier — it’s a brand advantage.

At Fumao, we combine technical expertise with aesthetic understanding to deliver kidswear collections that impress even the most detail-driven buyers. If you’re seeking a production partner that brings both quality and agility — we invite you to experience what modern China offers.