When it comes to the children’s clothing business, few things are more damaging than missing your season. Whether it’s spring styles stuck in customs or winter coats arriving in February, timing matters more than ever in 2025’s fast-moving retail landscape.

Seasonal collections are time-sensitive — and shipment delays can cost you entire quarters of profit. The damage is not only financial. It impacts your credibility with retailers, platforms, and end customers.

At Fumao Clothing, we work with many U.S. and European brands who demand on-time delivery for each season. In this article, I’ll break down the practical steps to help you avoid shipment delays when launching or replenishing seasonal collections. These are field-tested methods that work across supply chains from Asia to the U.S.

Why Are Seasonal Apparel Shipments So Prone to Delays?

Even well-planned apparel shipments can get caught in a web of delays. Understanding where the bottlenecks occur is the first step to avoiding them.

Apparel seasonality adds time pressure to a system already vulnerable to disruption.

What Are the Most Common Delay Triggers?

Seasonal shipments face delays due to:

- Peak shipping congestion (especially pre-holiday and back-to-school)

- Unreliable supplier lead times

- Incomplete export documentation

- Customs inspections

- Factory miscommunication

According to Freightos, over 27% of apparel shipments faced delays in 2023 Q4 due to last-mile port congestion alone.

How Does Apparel’s Seasonal Nature Make Timing Crucial?

Children’s fashion buyers often commit to trends six months in advance. That means delays compress your sales window, making you discount inventory sooner. A delayed summer shipment has little value by August.

Retailers like Nordstrom and Zulily penalize late shipments or cancel seasonal POs entirely. That’s why many brands now require firm DDP timelines from their factories.

How Can You Build Shipment Timelines That Actually Work?

Many brands build delivery dates based on ideal factory schedules — but this is a mistake. Your timeline must reflect reality across production, logistics, and third-party processing.

You need buffer zones and stage-specific accountability to keep seasonal schedules on track.

What Lead Time Benchmarks Should You Follow?

| Process Stage | Recommended Time (Working Days) |

|---|---|

| Sample approval | 7–10 |

| Bulk fabric prep/dyeing | 12–15 |

| Production (3000 pcs) | 15–25 |

| QC inspection | 2–4 |

| Booking & freight loading | 5–8 |

| Sea freight (China–USA) | 20–30 |

| Customs & final delivery | 3–7 |

Build backwards from your in-store or online launch. Always add a 10–15% time buffer. For more, read Flexport’s Apparel Freight Planning Guide.

How Can Software Help Manage Apparel Deadlines?

Use tools like Trello, ClickUp, or Anvyl to track pre-production, shipping, and milestone approvals. Real-time dashboards keep your team and factory accountable. At Fumao, we use shared Gantt charts and weekly check-ins to align seasonal deliverables with our U.S. buyers.

What Role Do Freight Partners Play in Avoiding Delays?

Many delays aren’t caused by the factory — but by unclear or reactive logistics planning. Working closely with your freight forwarder can help you choose faster, more reliable transport modes.

Don’t treat logistics as an afterthought — it’s a critical pillar in seasonal delivery.

When Should You Choose Air vs. Sea for Seasonal Apparel?

| Scenario | Best Mode | Notes |

|---|---|---|

| Short season window (e.g., Easter) | Air Freight | Use for last-minute shipments, <500 kg |

| Bulk mid-season refill | LCL Sea | Combine with DDP service |

| Pre-planned fall/winter launch | FCL Sea | Economical for 3CBM+ orders with 60-day buffer |

Refer to Maersk’s Mode Comparison for updated charts.

How Can Freight Forwarders Help Avoid Port Congestion?

Forwarders with local China offices can reserve containers in advance, reroute via less crowded ports, or advise rail-sea intermodal solutions. Companies like GeeseCargo offer DDP + bonded warehouse models that eliminate customs delays altogether. Always choose partners who understand fashion deadlines.

How Can You Improve Communication with Suppliers and Shippers?

Even the best timelines and forwarders fail if information doesn’t flow quickly. Communication errors or slow responses are a top cause of shipment delays.

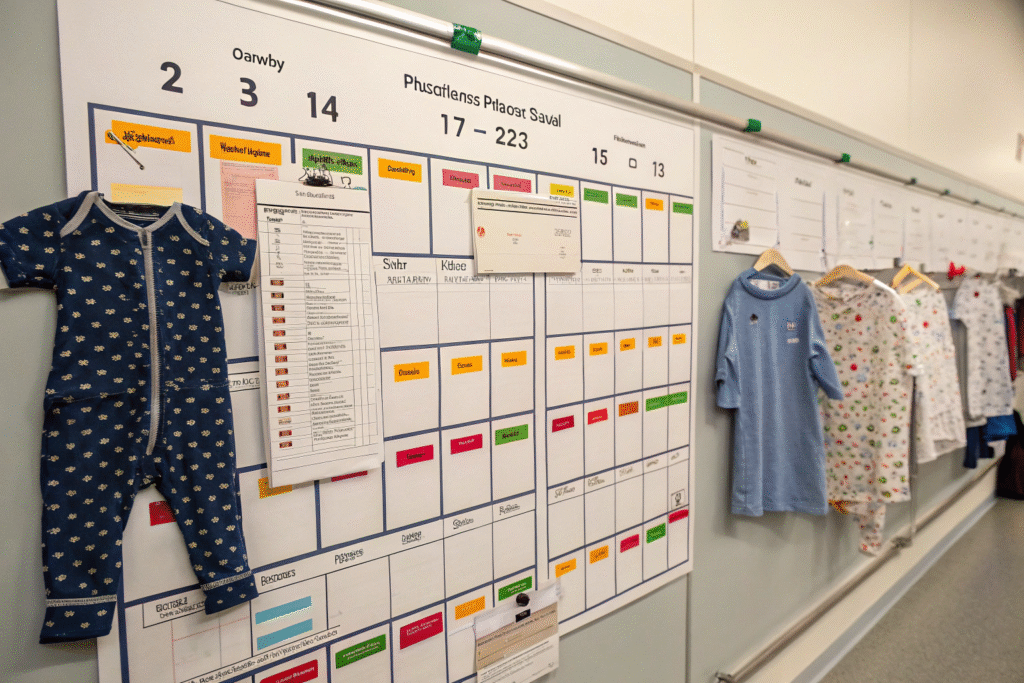

Clear, proactive, and visual communication keeps seasonal production and shipping aligned.

What Communication Habits Prevent Shipment Surprises?

- Weekly status updates via video call

- Shared production trackers with milestone checkboxes

- Immediate escalation on sampling delays

- Confirmed bookings (with BL#) before goods leave factory

- Pre-arrival customs documentation

Use tools like Slack for daily questions and Google Sheets for shared checklists. Also, implement file naming conventions for PO#, Style#, and Delivery Week.

How Can You Hold Suppliers Accountable Without Conflict?

Set SLAs (Service Level Agreements) during the PO stage. Include:

- Penalties for missed freight deadlines

- Expectations for inspection and label approval

- Definitions of “ready to ship” vs. “actual dispatch”

Good suppliers won’t be offended — they’ll be grateful you operate professionally. At Fumao, we work with brands that define exact cargo readiness dates and allow us to prepare weeks in advance.

Conclusion

Avoiding shipment delays in seasonal children’s clothing requires more than just asking the factory to hurry. It means building real timelines, choosing the right freight mode, improving communication, and managing every phase from sample to sail.

As a factory rooted in欧美童装 production, we understand how a delay in April can break a summer launch. That’s why we offer our clients a synchronized approach — from milestone-based production to logistics pre-booking and full DDP service.

If you’re tired of rushed shipping, late arrivals, or missed holiday deadlines — partner with a manufacturer who takes seasonal timing as seriously as you do.