The global demand for wholesale children’s clothing is booming—and more competitive than ever. As parents seek both style and safety, and as buyers like Ron in the U.S. chase profit margins without quality compromises, manufacturers like us must stay ahead of trends, compliance, and logistics.

Kids wholesale clothing is no longer just about volume—it’s about precision, safety, design flexibility, and certified production. At Fumao Clothing, we specialize in helping U.S. and European brands meet high expectations through streamlined, ethical, and efficient manufacturing.

If you’re a brand owner or sourcing director navigating the wholesale children’s wear landscape, this guide is tailored for you. Let’s dive into what really matters when choosing a trusted supplier and building a scalable, stylish, and profitable kidswear line.

What Makes a Children’s Clothing Manufacturer Reliable?

Finding the right supplier is the first and most crucial step. But in kidswear, there’s no room for error—safety, fabric integrity, and compliance define whether your goods make it past customs and into stores.

How Do You Know If a Supplier Meets Safety Standards?

When it comes to children’s clothing, international safety standards are non-negotiable. U.S. brands must comply with CPSIA, and European buyers follow REACH and OEKO-TEX guidelines. Ask your supplier whether they conduct third-party testing, and always request certification reports.

At Fumao Clothing, we partner with labs like SGS and Intertek to ensure every batch is tested for colorfastness, phthalates, and mechanical safety—especially important for infants and toddlers.

What Certifications Should You Look for?

The most common labels our clients require are OEKO-TEX® Standard 100, GOTS for organic fabrics, and BSCI or SEDEX for ethical labor compliance. These build trust with retailers and parents alike.

Many of our U.S. buyers also rely on Amazon’s product safety requirements and Walmart’s testing protocols when launching collections online. A reliable factory doesn’t just say they comply—they prove it.

Which Fabrics Work Best for Wholesale Kidswear?

Fabric selection drives everything—comfort, durability, compliance, and parent reviews. Brands that use poor-quality base materials suffer higher return rates and negative feedback, especially online.

Why Is Organic Cotton in High Demand?

Organic cotton is now a top-tier demand from U.S. and European clients. It reduces exposure to chemicals, is hypoallergenic, and offers eco-marketing value that drives parent trust. We source GOTS-certified cotton from reliable mills in China and India.

Sites like Pact and Mini Rodini showcase how organic fibers have become mainstream in mid to premium market segments.

Are Performance Fabrics Suitable for Activewear?

Absolutely. Our boys’ joggers and unisex hoodies often use poly-cotton blends with 5% spandex for 4-way stretch. These materials are lightweight, quick-dry, and suitable for school and playground wear.

We help clients select between jersey knits, French terry, and interlock fabrics, depending on end-use. Tillys Kids and The Children’s Place are great references for current fabric trends.

What MOQ, Lead Time, and Pricing Should You Expect?

MOQ (Minimum Order Quantity) is one of the biggest negotiation points for buyers. While many Chinese factories demand high MOQs, we’ve adjusted to offer low-MOQ custom solutions for brands testing SKUs or launching DTC.

What MOQ Works for Small to Mid-Sized Brands?

We offer MOQs as low as 300 pcs per style, with flexible sizing breakdowns. For example, a brand might do 300 pcs of one hoodie design split across 5 sizes (2T to 6T). This approach allows new brands to test the market before scaling.

Platforms like Faire and Handshake work well with factories offering flexible batch sizes, and our clients using these platforms see strong reorder rates.

How Long Should Production and Shipping Take?

Our typical timeline is 25–35 days for production and 12–18 days for air shipping, or 30–45 days for ocean DDP. Time can vary depending on fabric sourcing and embellishment methods.

We manage lead time using platforms like Flexport and ShipBob for freight and warehouse integration, giving brands real-time visibility.

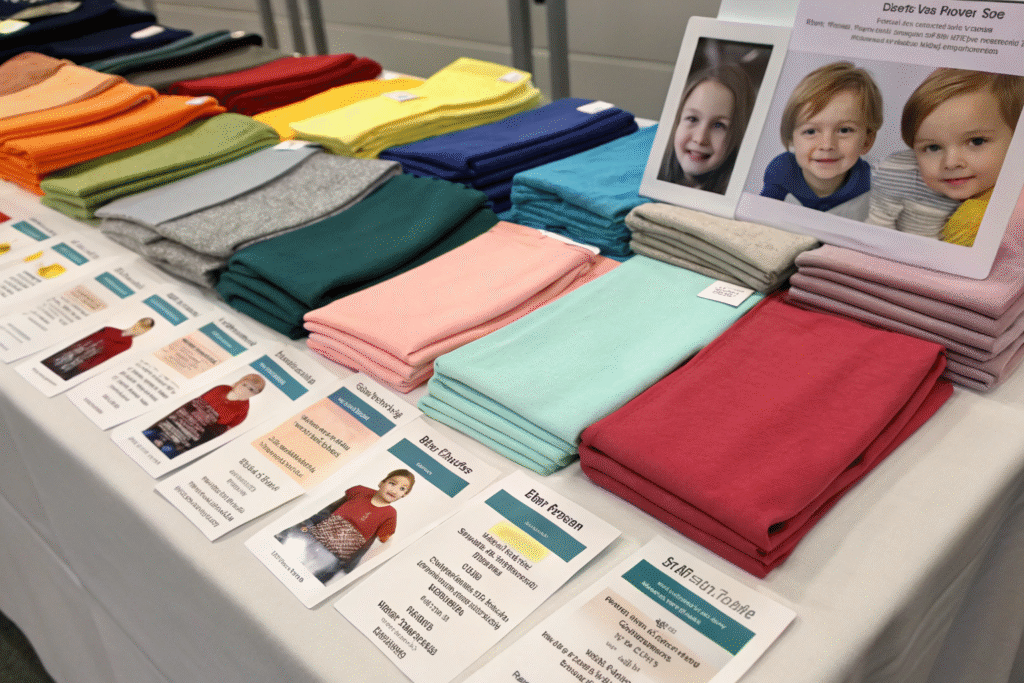

How to Ensure Brand Value Through Customization?

For many of our clients, including Ron, it’s not enough to simply receive bulk clothing. Branding adds perceived value and helps position even budget-friendly items as premium through thoughtful packaging and customization.

Can You Add Logos, Tags, and Retail-Ready Packaging?

Yes. We offer heat-transfer logos, woven neck tags, wash care labels, and even retail barcode stickers. Many buyers choose eco-packaging options like compostable polybags or recycled kraft sleeves.

Sites like Noissue and Sticker Mule demonstrate how packaging makes a difference. We integrate those same ideas into our DDP shipment process.

Do You Support Style Drops or Seasonal Capsules?

Absolutely. We work with several brands on monthly drops, offering limited-edition prints or embroidery updates for each season. This helps them stay on-trend and drive urgency with customers.

Using Shopify-integrated calendars and shared design dashboards (such as Trello or ClickUp), we ensure the production aligns with your eCommerce launch cycles.

Conclusion

The children’s wholesale clothing space has evolved into a competitive, quality-focused industry. Brands can no longer rely on price alone—they must ensure safety, comfort, trend alignment, and branding precision.

At Fumao Clothing, we don’t just manufacture—we solve sourcing challenges. Whether you’re launching a new line, scaling an existing brand, or expanding into the U.S. and EU markets, we’re here to provide compliant production, low MOQs, and on-time global delivery.

Let’s build your next collection the right way—together.