Sewing might sound simple, but behind every high-quality garment lies a complex process filled with precise execution, sharp problem-solving, and constant adjustments. Whether you’re producing in bulk or crafting samples, sewing presents challenges at every level.

The biggest sewing challenges include fabric handling issues, inconsistent stitching quality, machine breakdowns, operator training, and maintaining production speed without sacrificing accuracy. Each one can delay orders, increase rework, and affect the final product.

As a clothing factory owner working with brands across the U.S. and Europe, I see these issues daily. Let me walk you through what slows down even experienced sewing rooms—and how we handle it.

How do fabric types create sewing challenges?

Every fabric behaves differently under the needle. What sews beautifully one day might pucker, slide, or jam the next depending on fiber, weave, or finish.

Lightweight, stretchy, slippery, or layered fabrics create sewing challenges due to their handling complexity. Each fabric demands specific thread, tension, and machine settings.

Most difficult fabrics to sew:

| Fabric Type | Common Issue |

|---|---|

| Chiffon | Slipping, puckering |

| Jersey | Stretch distortion, needle holes |

| Denim | Needle breakage, skipped stitches |

| Satin | Visible needle marks, fraying |

| Rib knits | Uneven seams when stretched |

Our factory solutions:

- Adjusting feed dogs and pressure feet

- Switching to ballpoint or microtex needles

- Testing on scraps before production

- Stabilizing seams with interfacing or tape

Why is consistent stitch quality so hard?

Uniform stitching is one of the most visible signs of quality. But small inconsistencies happen—especially when switching fabric types, thread cones, or operators mid-shift.

Achieving consistent stitch quality is difficult due to operator fatigue, machine wear, and manual fabric control, especially on curves or multi-layer seams.

Common causes of bad stitching:

- Uneven seam allowance

- Improper tension settings

- Dirty feed dogs or bent needles

- Thread mismatch for fabric weight

How we reduce defects:

- Regular machine cleaning and tuning

- Training operators on curve control and back-tack accuracy

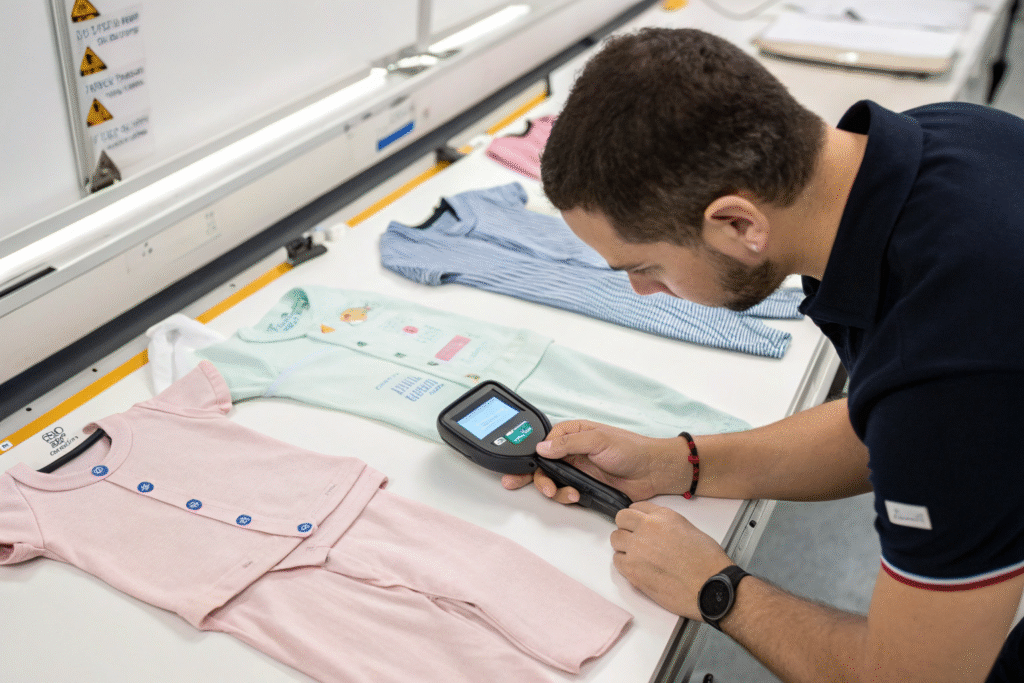

- Batch testing and visual QC after every 20–30 units

How do machine malfunctions impact workflow?

When machines stop, production stops. Even a five-minute breakdown can delay hundreds of pieces—especially if the line isn’t trained to switch machines or troubleshoot.

Machine malfunctions like skipped stitches, thread breakage, or power issues disrupt production flow and increase idle time in garment factories.

Most common failures:

- Broken needles or presser feet

- Looper misalignment in overlockers

- Servo motor overheating

- Poor thread quality jamming feed systems

Our preventative tactics:

- Daily inspection logs

- On-site mechanic during working hours

- Backup machines for key operations

- Pre-shift warm-up stitching on sample fabric

Why is operator training such a challenge?

Even the best machines can’t fix human error. A skilled sewing team takes months—sometimes years—to develop. Many new workers struggle with speed, seam accuracy, or specialty stitches.

Operator training is hard because sewing requires manual precision, speed, fabric knowledge, and the ability to self-correct while under pressure.

Common struggles:

- Keeping seam lines straight under pressure

- Matching fabric layers and notches

- Managing thread tension changes

- Switching between machines (lockstitch vs. overlock vs. coverstitch)

How we improve skills:

- Task-specific training by section

- Shadowing programs with senior workers

- Color-coded thread practice to evaluate seam alignment

- Incentives for low defect rates and speed improvement

Conclusion

Sewing is an art and a science. From challenging fabrics and machine errors to operator inconsistencies, the process requires constant monitoring, testing, and adaptation. In my own factory, we’ve reduced rework by 60% just through better training and preventive maintenance. If you’re sourcing from a manufacturer, ask them how they manage these challenges—it often says more than any showroom sample ever could.