Parents want safe, sustainable, and ethically made clothing for their children—but many don’t know how murky the kidswear supply chain can be.

Transparency in kidswear sourcing builds trust, protects brands, and ensures that garments meet ethical and quality standards. Suppliers who disclose sourcing details are more likely to maintain accountability, comply with regulations, and retain long-term buyers.

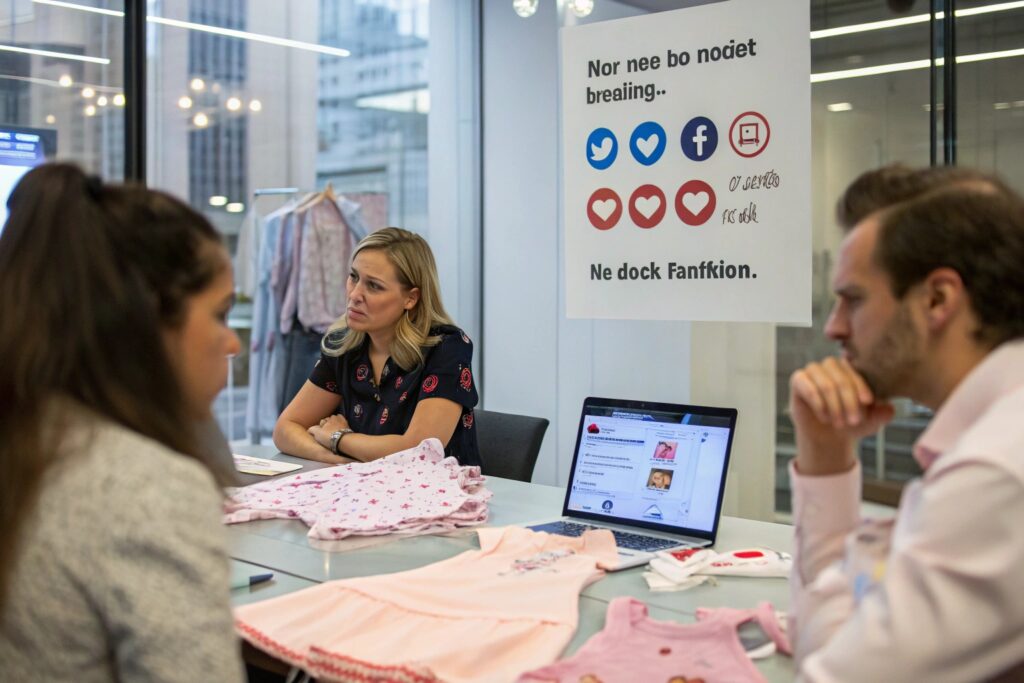

If you’re sourcing children’s apparel, lack of visibility can hurt your business. This is especially true in B2B where late deliveries, mislabeling, and poor factory practices can cost you sales and credibility. Let’s break down what transparency really means—and how it impacts your bottom line.

How Supply Chain Transparency Builds Consumer Trust?

Even the most stylish kidswear brand can face backlash if its supply chain hides labor violations or poor safety standards.

Supply chain transparency gives brands confidence to promote their products openly. It assures end customers that what they buy is ethically made, safe for children, and worth the price.

What do buyers look for when verifying if a kidswear supplier’s transparency claims are real and not just marketing fluff?

Buyers, especially from developed markets, don’t just want lower prices—they want reliability. But it’s hard to feel secure without real data. That’s why modern buyers often ask for factory audit reports, traceability records, and access to manufacturing certifications. When I first started Fumao Clothing, I quickly learned that U.S. and European clients ask very direct questions about our cotton sourcing, our factory’s working hours, and who does our inspections. If I couldn’t answer, they walked away.

Can factory-level transparency really prevent shipment delays or quality problems down the line?

Yes. When you can see exactly where your fabric is sourced, where each piece is sewn, and who signs off quality, you catch problems before they blow up. A transparent supply chain reduces blind spots that typically cause last-minute issues. For instance, I remember one instance where a client received mislabeled children’s coats because the subcontractor was not disclosed. That mistake cost us air freight fees and almost the client relationship.

Transparency forces accountability at every level. It shows who is doing what, when, and under which compliance standards. And for kidswear, where both safety and delivery timing are non-negotiable, it’s a game-changer.

Top Certifications Buyers Should Look for in Kidswear?

Certifications aren’t just fancy labels—they are the buyer’s insurance policy that garments are truly safe and responsibly made.

Look for globally recognized certifications like GOTS, OEKO-TEX, BSCI, and WRAP when evaluating kidswear suppliers. These confirm fabric safety, labor ethics, and environmental standards.

Why do kidswear brands insist on certifications when many factories say they follow “internal” safety and labor standards?

I get this question from factory owners all the time: “Why do they want BSCI when we already follow good practices?” The answer is simple—buyers can’t take your word for it. Certifications are third-party verified and universally accepted. Without them, it’s just a promise. And promises don’t get you listed on major retail platforms.

Which certifications are most trusted by American and European buyers when sourcing kidswear from countries like China?

Here’s a breakdown I often share with our clients:

| Certification | What It Covers | Why It Matters in Kidswear |

|---|---|---|

| GOTS | Organic textile production | Confirms natural, chemical-free fabric |

| OEKO-TEX | Harmful substance testing | Ensures no skin-irritating chemicals |

| BSCI | Social compliance in the supply chain | Verifies no child labor or forced work |

| WRAP | Ethical factory operations | Confirms safe, lawful working conditions |

When we onboard clients at Fumao Clothing, we send our certification files upfront—no need to ask. Because trust starts before the first order. And we keep them updated yearly.

Why Ethical Sourcing Is Vital for Children’s Apparel?

Children’s skin is sensitive. Their garments should be made from safe, soft, non-toxic materials—and produced without exploiting other children.

Ethical sourcing protects vulnerable communities and ensures children’s clothing meets safety, environmental, and social responsibility standards.

Are there hidden ethical risks in kidswear production that most buyers don’t see until it’s too late?

Yes. Many kidswear orders are subcontracted. That’s where the risks hide. I’ve seen cases where the main factory follows protocol, but hands off work to a small workshop using underage workers or harmful dyes. The buyer doesn’t find out until an audit—or worse, a media report. That’s why I never outsource any part of our production unless disclosed and agreed upon in writing.

How can ethical sourcing actually increase sales and not just cost more?

Buyers often assume that being ethical means being expensive. But that’s not the case. Ethical sourcing improves predictability. It also opens doors to retailers that won’t touch suppliers without proof of compliance. Some of our North American clients even use ethical sourcing as a brand value to justify premium pricing. When buyers know the source is ethical, they can sell with confidence.

Ethics is not charity. It’s smart business. Children’s apparel is a sensitive category—one media expose can kill a brand. Staying ethical shields you from reputation risks.

How to Audit Transparency in Your Kidswear Supplier?

Transparency isn’t a checkbox. It’s a process you can—and should—audit regularly.

Auditing your kidswear supplier involves verifying documentation, interviewing workers, reviewing production logs, and checking subcontractor disclosures.

What specific documents or factory data should I ask for before confirming a large kidswear order?

You should ask for:

- Factory audit reports (latest version)

- Production workflow chart

- List of subcontractors (if any)

- Fabric test results (preferably OEKO-TEX or GOTS)

- Social compliance certificates (BSCI, SEDEX, etc.)

- Photos of recent production batches

- Names of third-party inspectors (if used)

I once had a buyer from California request time-stamped sewing line photos. Sounds strange, but they wanted proof the order wasn’t being rushed at the last minute. We provided it. They re-ordered the next month.

Can digital tools or tech platforms make auditing easier and more trustworthy for overseas buyers?

Yes, absolutely. Today, some suppliers—including us—use digital platforms that log each stage of the order: cutting, sewing, QC, packing. These logs can be shared in real time with buyers. It not only builds trust, it also keeps everyone accountable. Here’s an example of a typical weekly log report we send:

| Stage | Status | Timestamp | Inspector Name |

|---|---|---|---|

| Fabric Cut | Completed | 2025-06-01 10am | Jack Liu |

| Sewing | In progress | 2025-06-03 4pm | Lisa Zheng |

| Final QC | Scheduled | 2025-06-07 | — |

| Packing | Pending | — | — |

Having this level of transparency means the buyer doesn’t need to chase updates. It also helps avoid disputes over timelines.

Conclusion

In the world of kidswear sourcing, transparency isn’t optional—it’s a competitive edge. For brands and buyers alike, working with ethical, certified, and fully traceable suppliers is the safest way to grow in this sensitive market.