Polyester is everywhere—from fast fashion to functional kidswear. But its petroleum-based origins, microplastic shedding, and slow decomposition make it a major sustainability concern. For buyers like Ron looking to sell conscious apparel in the U.S. or Europe, sourcing eco-friendly alternatives is no longer optional—it’s expected.

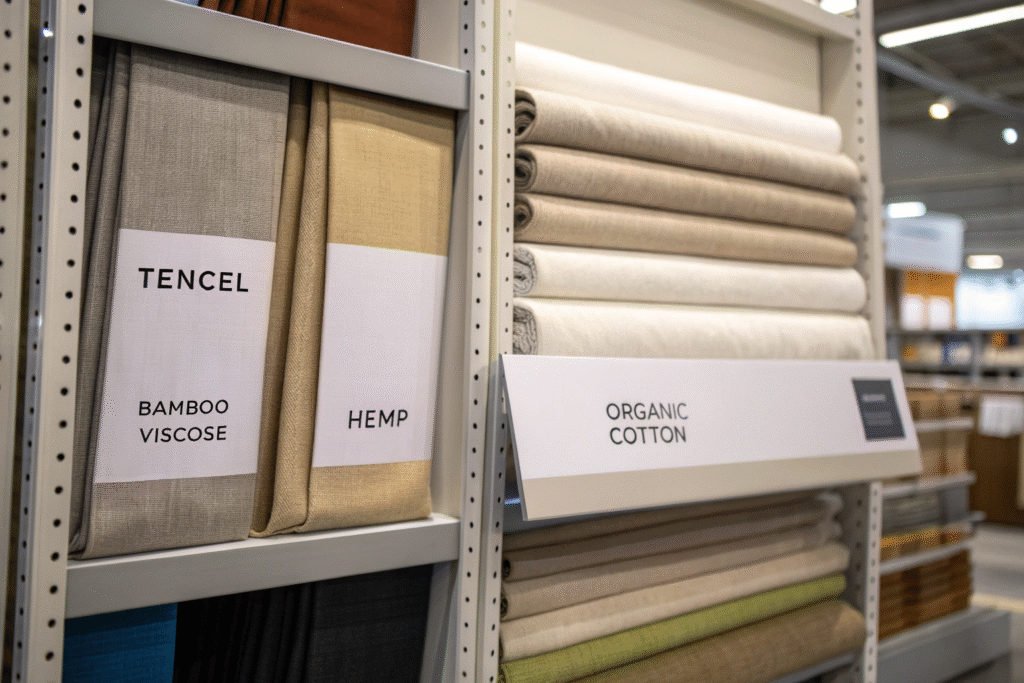

Sustainable alternatives to polyester include fibers like TENCEL™, bamboo viscose, organic cotton, hemp, and recycled polyester (rPET), each offering unique environmental and performance advantages.

Whether you’re launching a babywear line or upgrading your private label activewear, choosing the right replacement for polyester can reduce your carbon footprint and improve brand reputation. Let’s explore the most viable options for sustainable sourcing.

Why Replace Polyester in Apparel Production?

Polyester is cheap, durable, and wrinkle-resistant—but it’s also synthetic, fossil-fuel derived, and slow to degrade. Replacing it starts with understanding why it matters.

Polyester contributes to microplastic pollution, greenhouse gas emissions, and textile waste. Natural and recycled alternatives help reduce environmental impact.

What are the environmental downsides of polyester?

- Fossil fuel dependency: Made from petroleum

- Non-biodegradable: Takes up to 200 years to break down

- Microplastic shedding: Every wash releases plastic fibers into water systems

- High energy production: Polyester emits 3x more CO₂ than cotton during manufacture

According to Ellen MacArthur Foundation, polyester makes up 52% of global fiber production—and the majority ends up in landfills or incinerators.

What drives brands to choose sustainable options?

Today’s consumers expect transparency. According to McKinsey’s State of Fashion report, 67% of shoppers consider sustainability when choosing brands. Platforms like Amazon Climate Pledge Friendly also reward eco-certifications in listings.

Swapping polyester for eco-fibers helps brands meet buyer demands, achieve sustainability certifications, and reduce regulatory risks.

What Are the Top Natural Alternatives to Polyester?

Natural fibers offer breathability, biodegradability, and lower energy inputs. But not all are created equal. Understanding their sourcing and environmental profiles is key.

Natural alternatives like TENCEL™, bamboo viscose, organic cotton, and hemp offer softness, comfort, and reduced carbon impact compared to polyester.

Why is TENCEL™ a strong replacement?

TENCEL™ (by Lenzing) is made from FSC-certified wood pulp using a closed-loop system that recycles water and solvents.

Benefits:

- 50% lower carbon footprint than polyester

- Biodegradable

- Soft, moisture-wicking, and ideal for babywear

- Carries OEKO-TEX® and EU Ecolabel certifications

We source TENCEL™ Modal and Lyocell for baby rompers and sleepwear—popular for its silk-like hand feel and drape.

What makes bamboo viscose sustainable?

When processed with care, bamboo viscose is antibacterial, breathable, and biodegradable.

However, avoid chemically intensive versions. Choose closed-loop bamboo viscose, certified by OEKO-TEX® or GOTS.

At Fumao, we offer low-impact bamboo jersey with factory certifications—perfect for onesies, leggings, and sleep sets.

What Recycled Materials Can Replace Virgin Polyester?

If you still need the performance features of polyester (like durability or stretch), recycled versions offer a better environmental profile.

Recycled polyester (rPET) made from post-consumer plastic bottles cuts carbon emissions and reduces landfill waste.

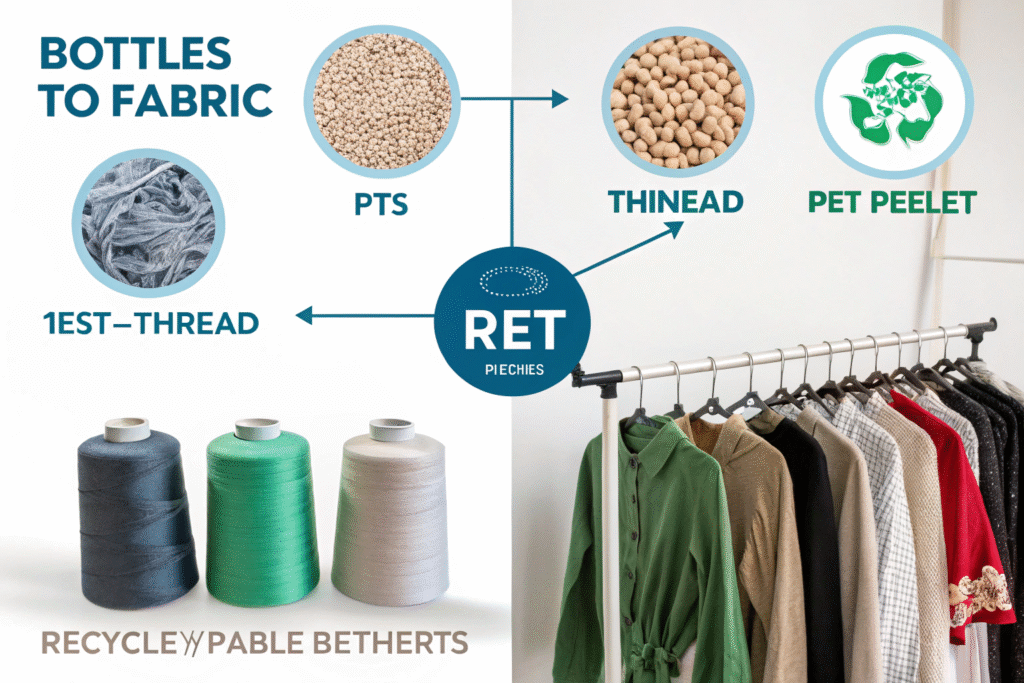

How is rPET made and used?

rPET is created by shredding PET bottles, melting them into chips, and re-spinning into yarn.

Advantages:

- 30–50% lower energy use vs virgin polyester

- Lower water consumption

- Maintains same strength and colorfastness

- Supports circular fashion

Be sure your supplier uses GRS-certified yarn and can provide traceability. We offer rPET French terry and interlock jersey for activewear and toddler joggers.

Are there any challenges with rPET?

Yes:

- Still sheds microplastics during washing

- Cannot be endlessly recycled

- Availability depends on regional recycling infrastructure

To minimize impact, combine rPET with Dope Dyeing techniques and use filter bags in end-customer packaging.

How to Verify Sustainability Claims from Fabric Suppliers?

Not all “eco fabrics” are truly sustainable. Many suppliers greenwash with vague terms like “eco polyester” or “natural viscose.” Real verification matters.

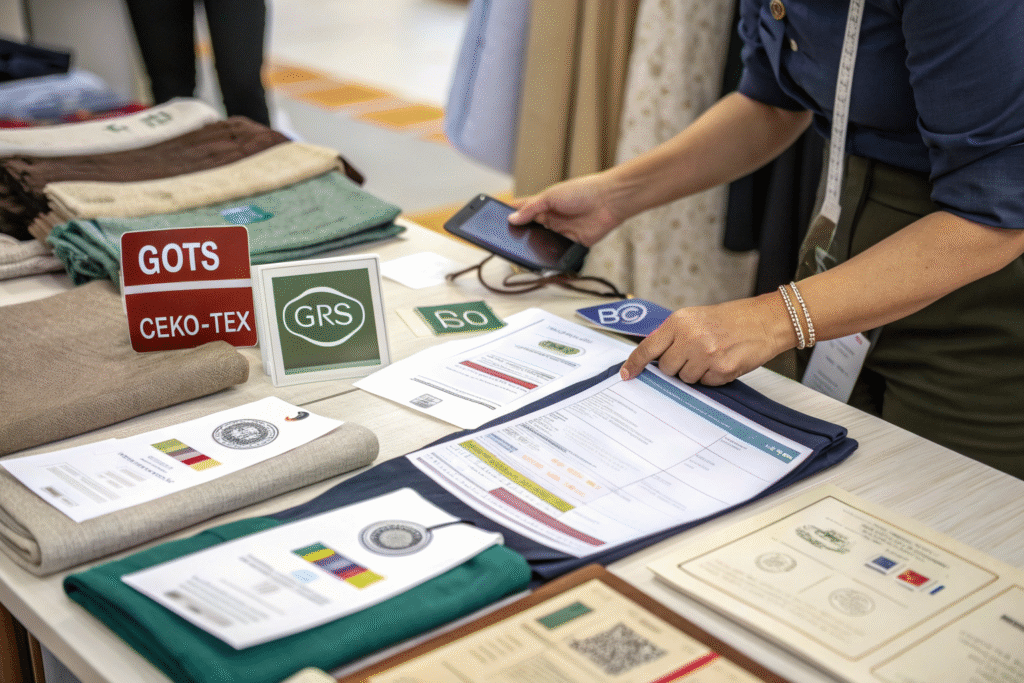

Use third-party certifications like GOTS, OEKO-TEX®, GRS, and FSC to validate the sustainability of polyester alternatives.

What certifications should you demand?

- GOTS (Global Organic Textile Standard): Organic fiber + social compliance

- GRS (Global Recycled Standard): Recycled fiber + traceability

- OEKO-TEX®: Free from harmful substances

- FSC: Certified wood pulp source for TENCEL™ and bamboo

We include digital scans of certificates with all fabric submissions to clients. Ask your supplier for recent certification validity (less than 12 months old).

How can buyers avoid greenwashing?

- Ask for batch-level traceability

- Request lab test summaries

- Use platforms like Texbase or Open Supply Hub to verify suppliers

Avoid vague terms like “eco,” “natural feel,” or “sustainable touch” without documentation.

Conclusion

Replacing polyester doesn’t mean sacrificing performance or affordability—it means choosing better. Whether you’re launching babywear, loungewear, or performance apparel, sustainable alternatives like TENCEL™, organic cotton, bamboo viscose, hemp, and rPET help build a greener supply chain and stronger customer loyalty.

At Shanghai Fumao, we offer GRS, OEKO-TEX®, and GOTS-certified fabrics that meet U.S. and EU standards for eco-conscious production. Want to explore our sustainable fabric book or develop a custom babywear line using polyester-free blends? Contact our Business Director Elaine at elaine@fumaoclothing.com and we’ll help you make the switch—seamlessly.